Full Service

Includes troubleshooting, genuine parts and expert service as well as repairs.

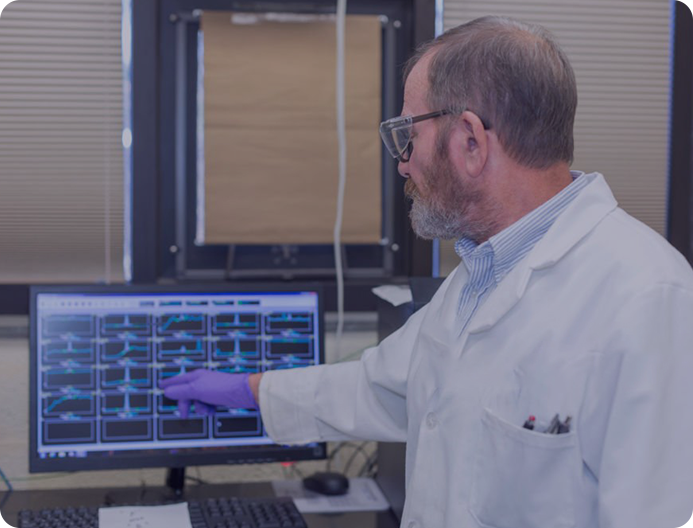

Experienced technicians

Our well-trained and experienced technicians know your machine inside and out. They can spot potential problems early to prevent breakdowns.

Remote monitoring

With intelligent control system, remote monitoring can be made successfully. It is easy to ma.ke risk sharing and energy efficiency optimization on-line.

A green solution

Upholding the energy efficiency of your equipment means minimizing the environmental impact and achieving your energy saving targets.

Spare parts

Two years operation spare parts are provided with delivery.

Fast Response

24-hours a day, 365 days per year. Our service experts monitor all the relevant blower data and respond as priority to your needs.

Choosing the right type is the first step in energy saving and ensuring normal operation. MARWELL's technical team will assist you in evaluating, analyzing, and improving the efficiency and performance of your air systems.

Assessing your requirements for the blower system

Different industries have different requirements for blower systems. MARWELL's technical team selects the most suitable products for customers based on the specific needs of each project. Through data analysis and comparison, we provide clients with the most reasonable advice, including project-specific designs and energy-saving solutions.

We are fully involved in customer solution design, product selection, and ensuring necessary parameters are adjusted in advance before shipping, to achieve maximum plug-and-play service from start-up to operation. Manwell's technical team will be involved throughout the project commissioning process to ensure smooth and stable machine operation.

We offer accurate design tolerances, ensure problem free replacement of parts and longer plant life through use of genuine spare parts in spare part supply which is one of the most important components of our After Sales Services.

If you have purchased a magnetic levitation compressor or blower, congratulations, as you won't need to spend time and effort on maintenance. Regular replacement of filter is the only task you need to perform.

Depending on the project requirements, if you need to choose models other than magnetic bearing compressors or blowers, regular maintenance and routine upkeep are essential for efficient product operation. Once your compressor system is successfully installed in your factory, MARWELL's service team will assist you in developing an equipment maintenance plan. Our service and maintenance guidelines cover the foundational knowledge to keep your factory's compressed air system running smoothly.