OKI is the largest paper mill in Indonesia. In the process of achieving its carbon neutrality goals, it has continuously increased investment in technology research and development and selected efficient and energy-saving equipment to reduce energy consumption, optimize the working environment, and accelerate the carbon neutrality process. Before the technical upgrade, the OKI project used Roots blowers for air supply. The original blowers were noisy, had high vibration, and, after years of use, experienced a significant reduction in airflow, making it difficult to meet operational needs. In 2024, they chose 10sets marwell magnetic bearing blowers to replace the original Roots blowers for the lime kiln system air supply. The conclusions from the acceptance test are as follows:

Approximately 33% energy savings compared to the original Roots blowers.

Increased system stability.

Reduced maintenance costs.

Improved working environment with significantly reduced noise and vibration.

Intelligent operation with visualized operational data.

Project Site

Comparison of Operating Conditions between the Original Roots Blowers and the magnetic bearing blowers:

Blower Type | Roots Blower | marwell magnetic bearing blower |

Number of Blowers | 10 units | 10 units |

Air Flow per Unit | 880 m³/min |

|

Pressure | 49 kPa |

|

Power per Unit at Operating Point | 250 kW | 166.7 kW |

Total Power | 2500 kW | 1667 kW |

Energy Saving Rate |

| 33.32% |

Note: The energy savings in the table are calculated based on the nameplate data of the Roots blowers. The actual efficiency of the old blowers has significantly decreased due to aging, so the actual energy savings are higher than estimated.

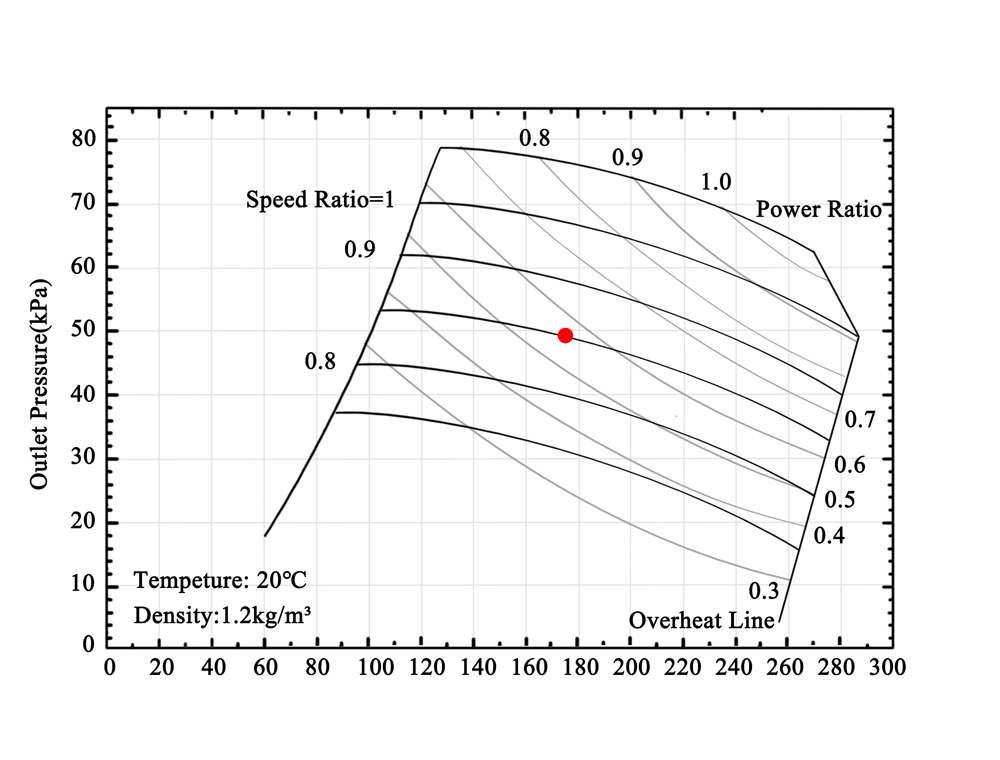

Performance Curve of magnetic bearing blowers under the Same Conditions:

Advantages of marwell magnetic bearing blowers:

1.Energy Efficiency: The high-speed motor is directly coupled to the impeller drive, without friction, achieving high-speed stepless speed regulation, saving over 30% more energy compared to Roots blowers.

2.Low Noise: The magnetic bearing bearing adopts self-balancing technology, with vibration levels an order of magnitude lower than traditional bearings. It features an active vibration damping design, ensuring stable operation with minimal body vibration, and blower noise around 80dB(A).

3.Intelligent Control: It can monitor the blower's operating status in real-time, achieving intelligent and manual multi-mode control of airflow, air pressure, and speed. "marwell" enables remote operations and maintenance.

4. Maintenance-Free: The magnetic bearing blower is frictionless and 100% oil-free, requiring no mechanical maintenance, only the replacement of filter cotton and filters.

Additionally, various stages of the paper-making process use vacuum pump equipment. With years of expertise in the magnetic bearing fluid field, marwell Environment has developed a magnetic bearing turbine vacuum pump. Compared to traditional water ring vacuum pumps, it offers higher energy efficiency, saving over 40% energy, and features 100% oil-free operation, low noise, and easy maintenance.

Due to the excellent performance of magnetic bearing fluid equipment, marwell Environment has significantly reduced operating costs and improved system stability. These products have been widely applied in nearly a hundred paper-making enterprises domestically and internationally. To date, thousands of magnetic bearing products have been efficiently and energy-savingly used in regions both inside and outside the country, making significant contributions to achieving "dual carbon" goals.