In the pharmaceutical manufacturing process, wastewater is generated, and aeration blowers are needed for biochemical reactions during the wastewater treatment phase. The pharmaceutical factory's previously used roots blowers were outdated, resulting in significantly reduced performance and insufficient aeration to meet production requirements. Additionally, roots blowers require substantial daily maintenance, consume high energy, produce significant noise, and have poor flow regulation, causing considerable inconvenience to users.

Having previously used four Marwell Magnetic bearing Blowers in a wastewater treatment station upgrade project, which significantly reduced operating costs and improved system stability, the pharmaceutical factory opted once again to upgrade the original roots blowers with high-efficiency Marwell Magnetic bearing Blowers.

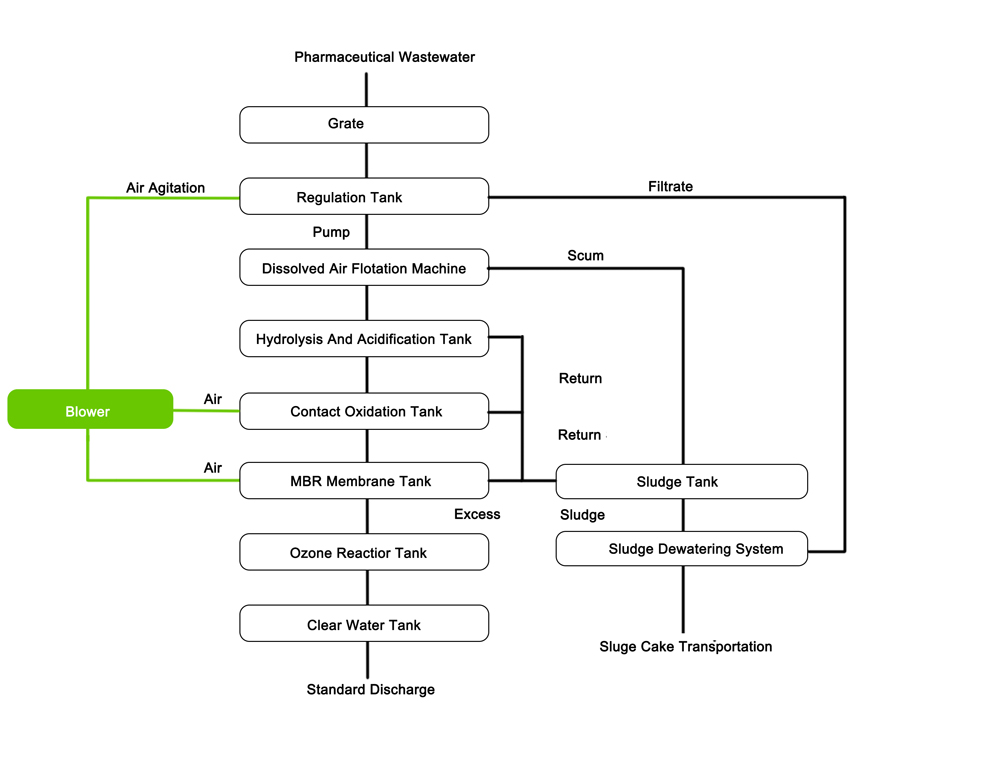

Pharmaceutical Wastewater Treatment Process

As shown in Table 1, the total flow rate of the original blowers was 79.6 m³/min, the pressure was 68.6 kPa, and the total power was 150 kW. The existing airflow could not meet production needs, so additional airflow was required. One MTB-150 Marwell magnetic bearing blower was selected to replace the original roots blower, with the original roots blower kept as a backup.

Table 1: Original Roots Blower Parameters for the Wastewater Treatment Station

Number of Root Blower | Nameplate Pressure | Nameplate Flow Rate | Nameplate Power | Operating Status |

2sets | 68.6kPa | 39.8m³/min | 75kW | Full Load |

Table 2: Magnetic bearing Blower Parameters

Number of Magnetic bearing Blowers | Nameplate Pressure | Nameplate Flow Rate | Nameplate Power |

1set | 68.6kPa | 100m³/min | 150kW |

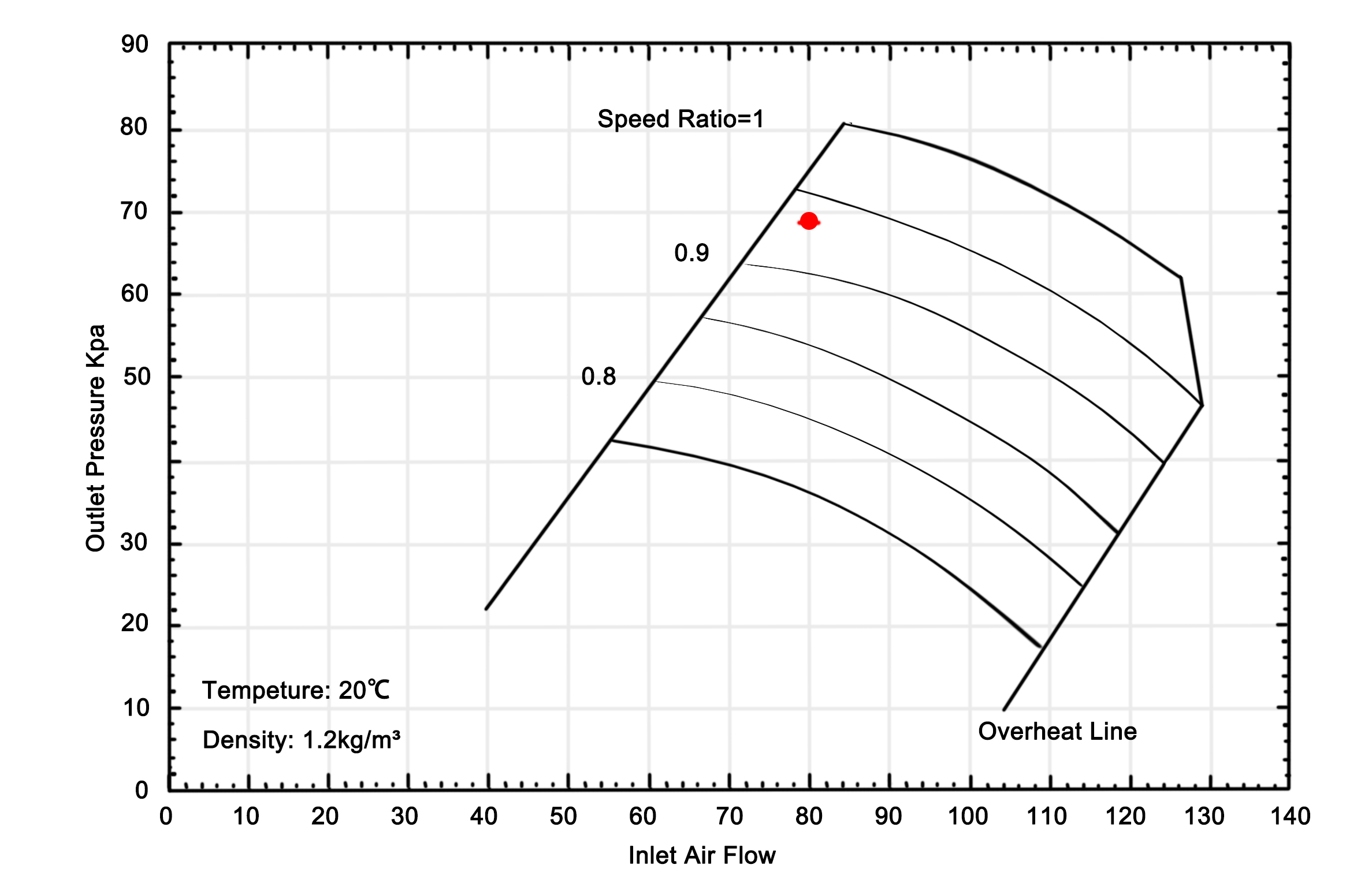

Performance Curve of MTB-150 Magnetic bearing Blower

Working Point Flow Rate: 79.6 Nm³/min

Working Point Pressure: 68.6 kPa

Working Point Power: 96 kW

Project Site and Blower Operation Status Interface

(Project Magnetic bearing Blower Operation Status Interface)

Comparison of Old and New Blower Performance

Project | Magnetic bearing Blower | Roots Blower |

Size | Small volume, small footprint | Large volume, large footprint |

Installation | No special foundation required | Requires special foundation |

Blower Room Design | Small footprint | Large footprint, increased costs |

Vibration | Low vibration | High vibration |

Noise | Noise below 80 dB (no soundproof cover needed) | Noise around 110 dB, requiring soundproofing and noise reduction measures |

Maintenance | No need to replace lubricating oil, only replace filter cotton filter | Regular replacement of lubricating oil required |

Operation | Touch screen intelligent control, remote operation and maintenance | Common variable frequency drive with low efficiency, affecting motor cooling and lifespan |

Efficiency Comparison of Old and New Blowers

Comparison of Operating Conditions Between Marvel Magnetic Levitation Blowers and Original Roots Blowers After Technical Upgrade:

Blower Type | Roots Blower | Magnetic bearing Blower |

Number of Operating Blowers | 2sets | 1set |

Single Blower Flow Rate | 39.8m³/min | 79.6m³/min |

Outlet Pressure | 68.6kPa | 68.6kPa |

Single Blower Output Power | 75kW | 96kW |

Total Power | 150kW | 96kW |

Energy Savings Rate | 36% | |

Project Summary:

From the on-site operation of the blowers, the application effect of the Magnetic bearing Blowers is far superior to that of the original roots blowers, with advantages mainly in:

Low Energy Consumption: Approximately 36% energy savings compared to the original roots blowers.

Low Noise: Noise reduced from the original 110 dB (A) to ≤ 80 dB (A).

Easy Maintenance: Transition from regular lubrication and filter cotton replacement to only needing to replace the filter cotton filter.

Easy Operation: Smart operation via touch screen for on/off and flow adjustment.

Marwell bearing blowers have been efficiently applied in many fields, including wastewater treatment, metal oxidation, biological fermentation, material transport, and flue gas desulfurization, among others. Marwell Environment has thousands of magnetic bearing Blowers in high-efficiency applications domestically and internationally, saving approximately 30% in energy compared to traditional blowers, with features like oil-free, no mechanical maintenance, low vibration, low noise, easy installation and maintenance, remote operation, and self-generated multi-protection, continuously helping customers in various industries reduce costs and increase efficiency, earning unanimous praise from users and industry experts.