The upgrade of municipal wastewater treatment enterprises primarily involves optimizing control through intelligent systems and adopting new technologies. This ensures that wastewater treatment facilities operate efficiently and economically while reducing energy consumption, material consumption, chemical consumption, and carbon emissions. Generally, wastewater biological treatment equipment and installation account for about 40% of the investment. Equipment energy consumption (mainly for aeration and oxygen supply) accounts for 50%-70% of the total energy consumption. After construction and operation, the daily maintenance and major repairs of the equipment are also major factors in the direct operating costs.

Traditional Blowers with High Energy Consumption and Complex Maintenance are Gradually Being Eliminated from the Market, and Choosing Efficient and Energy-Saving Magnetic Bearing Blowers Has Become an Industry Trend.

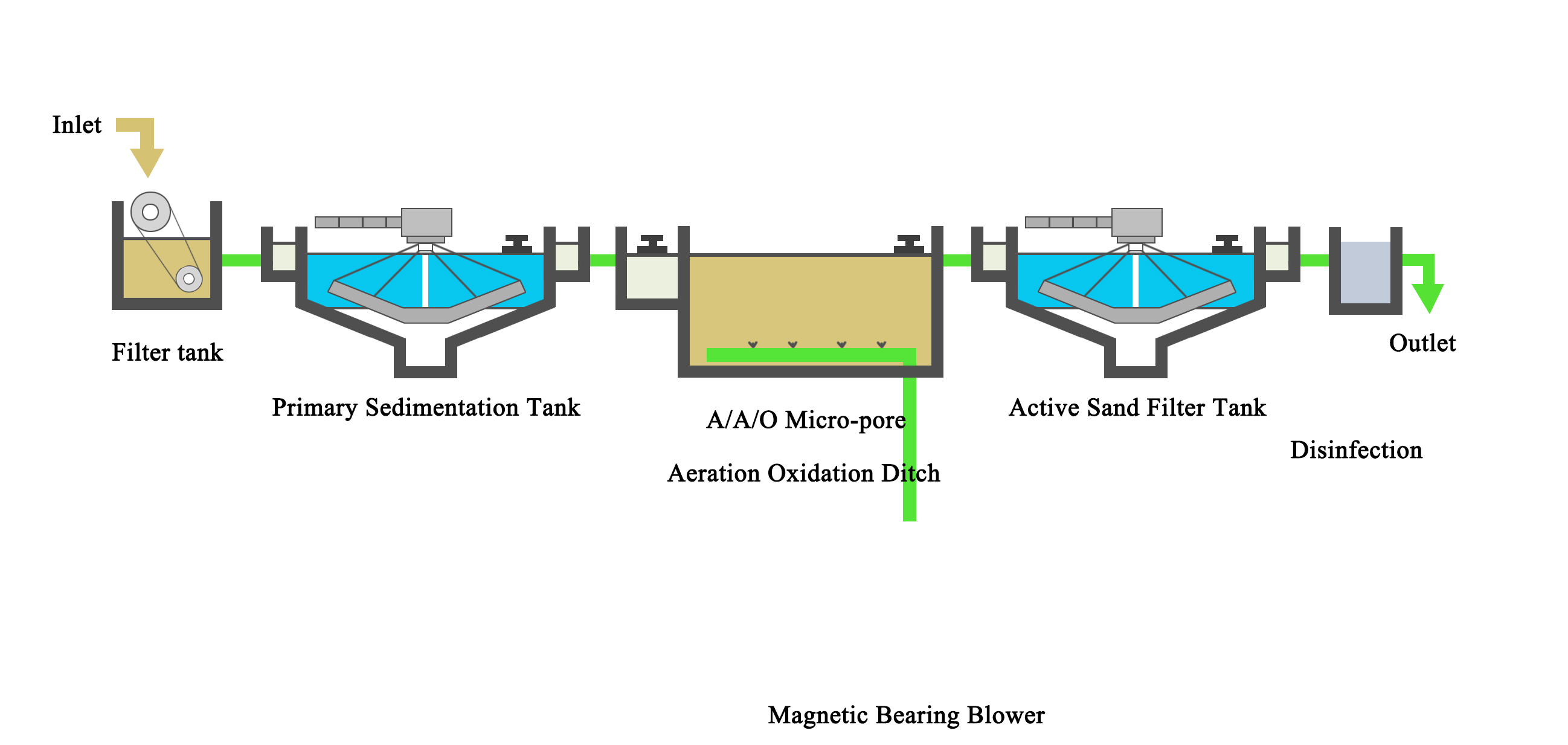

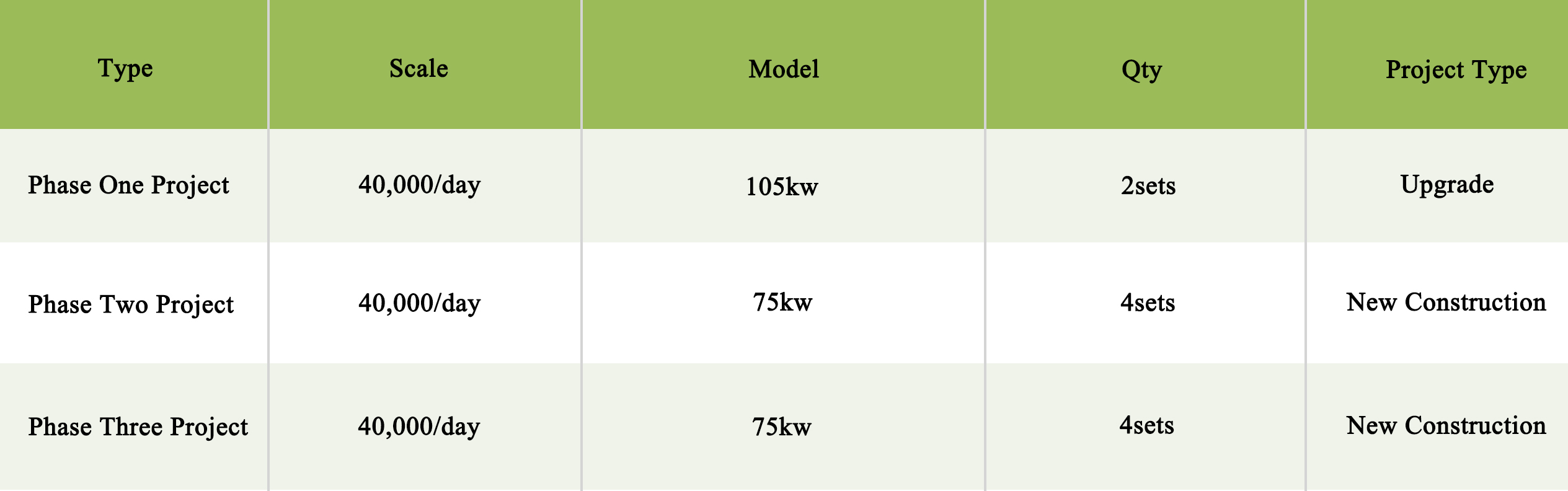

This wastewater treatment plant was constructed in 2016, adopting the relatively advanced wastewater treatment process of A2O micro-aerated oxidation ditch combined with an active sand filter. The total wastewater treatment capacity is 120,000 tons per day. Currently, three phases have been completed and are operational, each with a design capacity of 40,000 tons per day.

A total of 10 magnetic levitation centrifugal blowers are installed. Compared to wastewater treatment plants using traditional blowers, the energy consumption per ton of treated wastewater is significantly lower. The Magnetic Bearing Blowers are driven by high-efficiency synchronous permanent magnet motors and use magnetic levitation bearings with no mechanical wear. The blower impellers operate in the high-efficiency zone, and specialized frequency converters provide efficient electric drive, saving about 30% more energy compared to traditional Roots blowers.

Phase Three Project Site

The magnetic levitation blower bearings utilize self-balancing magnetic levitation technology, resulting in vibration levels that are an order of magnitude lower than traditional bearings. They feature active vibration damping design, ensuring stable operation and minimal body vibration. The operating noise of the Magnetic Bearing Blowers is low, significantly improving the plant environment and meeting environmental requirements for boundary noise levels.

Click to view measured vibration data.

Additionally, Magnetic Bearing Blowers have a wide range of frequency adjustment for wind pressure and flow, making them better suited to adapt to changes in wastewater plant volume and quality. They are more flexible than traditional blowers and integrate the "Marwell" remote management system, allowing real-time online monitoring of blower operating status. Control parameters can be adjusted promptly, making aeration volume adjustment more precise.

Advantages of Magnetic Bearing Blowers:

1.Energy Efficient: About 30% more energy-saving compared to traditional Roots blowers.

2.100% Oil-Free: No need for lubricating oil, enabling 100% oil-free air output.

3.Low Noise and Low Vibration: No mechanical contact or friction between rotating and stationary parts inside the blower, resulting in low vibration and noise levels below 80dB(A).

4.Maintenance-Free: Magnetic Bearing Blowers are frictionless, requiring no mechanical maintenance, only replacement of filter cotton and filters.

Remote Operations and Maintenance: "Marwell" allows real-time monitoring of blower operating status and enables remote operations and maintenance.

Due to the excellent performance of Marwell Magnetic Bearing Blowers, operating costs have been significantly reduced, and system stability has improved. Currently, thousands of units are widely used in over a hundred municipal projects domestically and internationally.