Milk, often referred to as "white blood," is not only rich in protein but also contains important minerals such as calcium and phosphorus. These elements are crucial for human health.

In the processing of milk, strict disinfection and sterilization are employed to ensure quality. As a result, a large amount of wash water is used to clean production equipment and areas. Statistics show that producing one ton of liquid milk can generate approximately 2.5 tons of dairy wastewater. If this wastewater, which contains high concentrations of organic matter, is discharged without treatment, the soluble organics can cause eutrophication of water bodies, thereby affecting water quality. Hence, such wastewater needs to be rigorously treated before discharge.

Modern dairy processing plants often use aerobic biological treatment methods. Blowers supply air to microorganisms in the sewage tank, allowing them to efficiently decompose the organic matter in the wastewater under sufficient oxygen conditions, thereby purifying the wastewater.

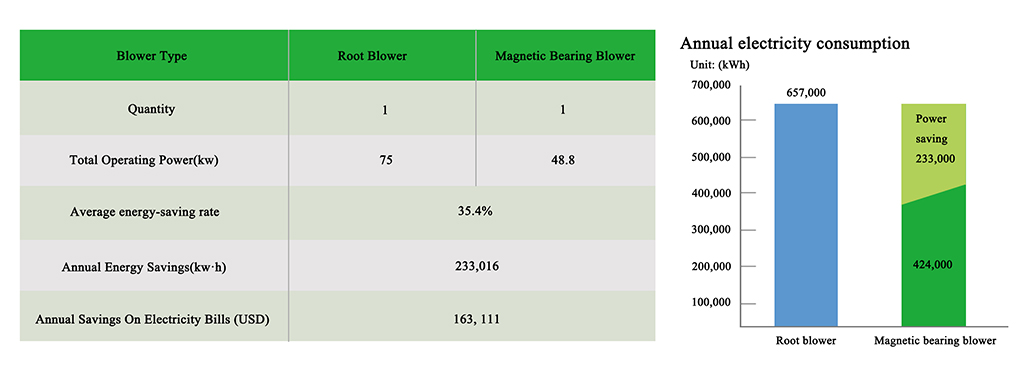

Case Study 1: Mengniu Dairy, 35.4% Electricity Savings

The operating costs of Mengniu Dairy’s wastewater treatment station are largely attributed to electricity, consuming 0.4-0.6 kWh per cubic meter of wastewater, accounting for about 40%-50% of the treatment costs. Traditional blowers consume high energy, produce significant noise, and their airflow decreases as they age and parts wear out. To reduce energy consumption, the company replaced its original roots blowers with Marwell magnetic bearing blowers. With unchanged operating conditions, the operating power decreased from 75 kW to 48.4 kW, achieving a 35.4% electricity savings and saving approximately USD23,000 in electricity costs annually.

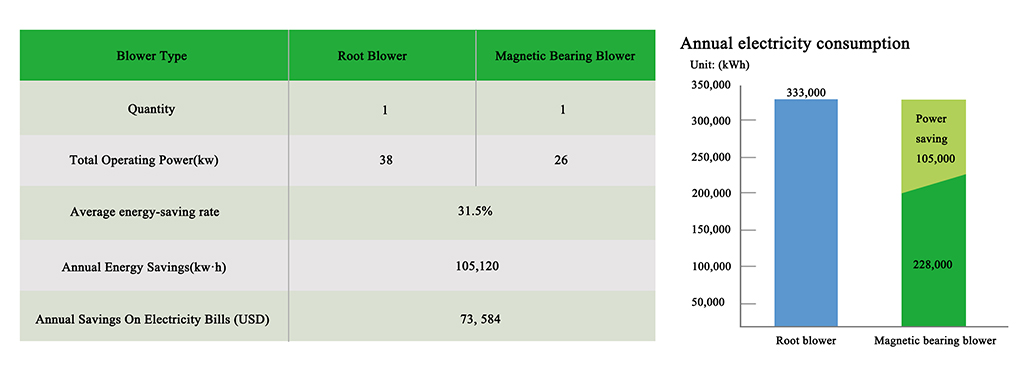

Case Study 2: Bright Dairy, 31.8% Electricity Savings

Bright Dairy’s wastewater treatment station originally used a 32 kW roots blower for aeration, paired with two 3 kW electric mixers, totaling 38 kW of operating power. To reduce energy consumption, the company chose Marwell magnetic bearing blowers for equipment upgrade after multiple comparisons.

Post-upgrade, the operating power decreased from 38 kW to 26 kW, significantly reducing energy consumption at the wastewater station, achieving a 31.8% electricity savings and saving about USD10500 in electricity costs annually. Maintenance costs also dropped from USD3,000 per year to USD3,00 per year, greatly reducing maintenance expenses.

At the same time, Marwell magnetic bearing blowers also participate in supplying air to sludge thickening tanks, achieving overall optimization of the wastewater aeration system.

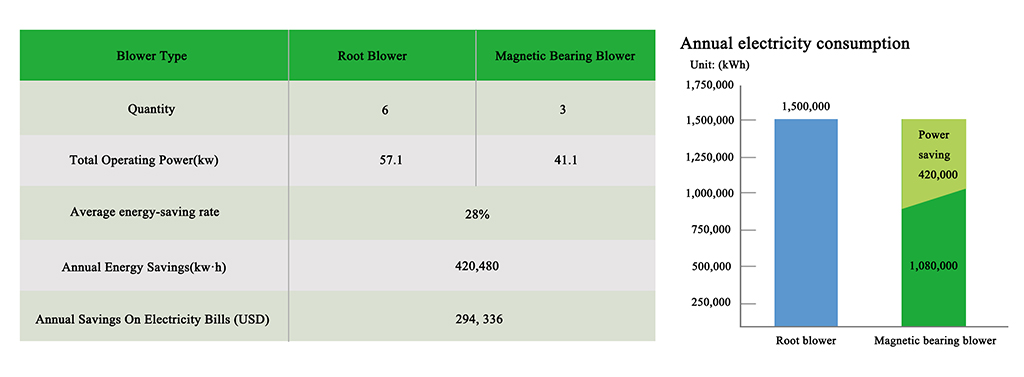

Case Study 3: Yili Group, 28% Electricity Savings

Yili Group’s wastewater treatment station previously used six roots blowers for aeration. Due to prolonged operation, the equipment’s daily electricity consumption and maintenance costs increased annually. To reduce energy consumption, the company decided to upgrade the original equipment. Marwell’s technical personnel responded promptly to the customer's energy-saving needs, conducting on-site inspections and data calculations, and custom-designed an energy-saving solution. Three 50 kW Marwell magnetic bearing blowers replaced the original equipment.

After the upgrade, with unchanged operating conditions, the operating power decreased from 57.1 kW to 41.1 kW, achieving a 28% electricity savings and saving about USD 42,000 in electricity costs annually.

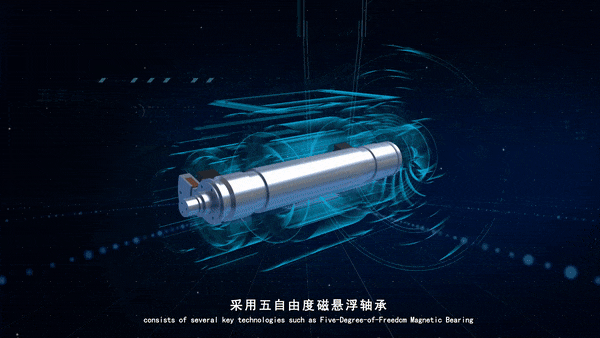

As a new type of energy-saving blower, magnetic bearing blowers use magnetic levitation bearing technology, ensuring the rotor remains stably levitated during operation. Driven by high-power, high-speed permanent magnet synchronous motors, these blowers operate continuously on gas using three-dimensional fluid impellers. Compared to traditional roots blowers, they save about 30% in energy, offering advantages like "zero friction, more reliability, higher energy efficiency, 100% oil-free, and maintenance-free."

So far, Marwell Environment has nearly ten thousand magnetic levitation energy-saving products efficiently applied domestically and internationally, contributing to the realization of global carbon goals.